Awards

For more than 90 years, DGS Druckguss Systeme AG has been manufacturing high-quality die casting parts in various alloys for different industries. Our expertise lies in the fulfillment of customer needs with the best technologies.

Awards in chronological order

2024 | DGS receives the Innovation Award of the German Foundry Industry

DGS Druckguss Systeme AG receives the Innovation Award of the German Foundry Industry Peter R. Sahm

In recognition of their outstanding contributions to innovations in foundry technology, DGS Druckguss Systeme AG was awarded the prestigious Innovation Award of the German Foundry Industry Peter R. Sahm. The award ceremony took place during the Great Foundry Technical Conference 2024 in Salzburg, attended by 650 leading industry representatives. DGS Druckguss Systeme AG has excelled in the foundry industry through continuous innovation and a pursuit of excellence. This recognition reflects the company's commitment to advancing the industry with advanced solutions and improving the efficiency and quality of processes. The credit for this achievement goes to all employees of the DGS Group at all locations.

2018 | DGS & Audi awarded with 1st prize for Verbindungsteil CD at Euroguss

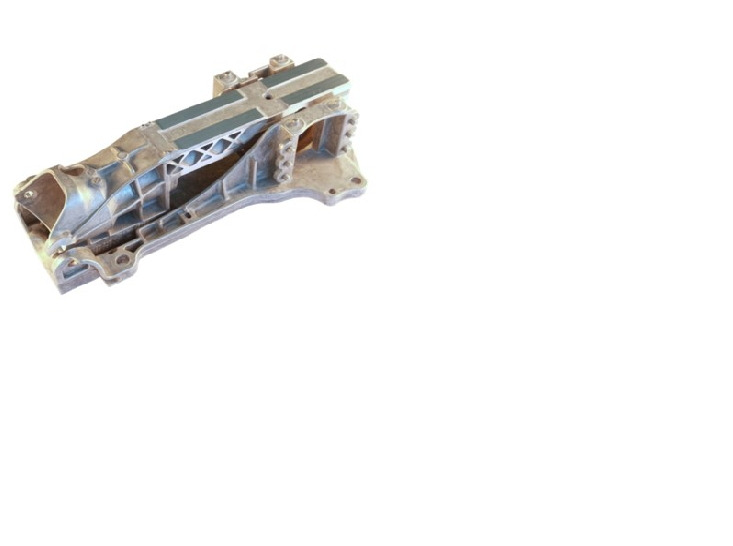

Milestone in lightweight construction

The joint development with Audi AG in Neckarsulm was honored at the international die casting competition in Nuremberg. The special feature lies in the optimized design of the casting which led to a weight reduction of -19% compared to the functionally identical part of the predecessor model (Audi A8 D5). This was achieved with a high-strength, highly flowable alloy in combination with a strength-optimized T6 heat treatment. The thin-walled design also saves a significant amount of material, thus contributing to a sustainable value chain.

2016 I Award at Euroguss for Hörbiger gearshift housing

Special acknowledgment from Hörbiger for gearshift housing

DGS has received a prize for innovative solutions in lightweight construction for casted housing manufactured in the Czech Republic.

2014 I Special recognition for Hoval solar frames at the Euroguss die casting competition

Contribution for renewable energy

DGS was awarded with the Euroguss 2014 prize for the production of the largest European high-pressure die casting part in one shot. The solar frame weighs 6.4 kg with record dimensions of 2050 x 1230 x 54 mm.

2013 I Frame for solar collector made of aluminum die casting

DGS has taken-up production of the largest European casted part in its location in St. Gallen, Switzerland

The 2 meter long casted part forms the frame of a solar module and allows the design engineer great freedom of engineering with high stability despite the particularly small mounting dimension. As a result, complicated welding lines which are always problematic with respect to long-term sealing can be prevented. Thanks to a special aluminum alloy, the frame can be used without special surface protection.

2012 I DGS receives again an award for the structural part of the Audi A8 at EUROGUSS 2012

At the opening ceremony of the EUROGUSS, DGS was awarded the first prize for the Audi A8 space-frame longitudinal beam

Due to its complex geometry the part is particularly difficult to produce. High integration of functions in the thin-walled area and achieving tight accuracies are crucial. The longitudinal beam is produced in the casting process as a part and later on welded with other components.

2011 I GIFA Newcast award for innovative castings

During the GIFA Newcast DGS is being honored for innovative solutions in lightweight construction

The manufacturing process developed by DGS for the longitudinal beam for Audi replaces the previously used production process.

2011 I Steering parts for global platform program of a premium manufacturer with about 1.8 million vehicles per year

DGS Druckguss Systeme AG supplies numerous magnesium steering components in large quantities for various platforms of a German premium car manufacturer

These parts are casted on several converted fully automatic die casting cells from a high-ductile magnesium special alloy which has been specifically designed for the customer's requirements. The semi-finished products are subsequently processed further with automated high-speed machining centers and delivered in assembly-ready packaging.

The high-ductile alloy requires very comprehensive process competency since the casted parts are challenging in terms of deformation and cracking requirements.

The high-ductile alloy requires very comprehensive process competency since the casted parts are challenging in terms of deformation and cracking requirements.

2010 I First prize at the Euroguss competition for an air-dryer housing application of Knorr-Bremse

As competent partner DGS also manufactures almost impossible parts

DGS receives first prize at the Euroguss competition for complex air-dryer housing of the customer Knorr-Bremse.

2009 I

Supplier of the year at Knorr-Bremse

Award for DGS as premium supplier

In 2009 DGS was awarded with the supplier prize for various housings and cover parts from Knorr-Bremse.

2008 I Award at the Euroguss 2008 for air exhaust grid for the Audi R8

Innovative casting from DGS

Award for DGS at Euroguss 2008 for an air exhaust grid for the Audi R8.

2005 I VW Group award for handbrake development

Weight reduction in braking systems

DGS

was able to reduce the weight of the handbrake systems in the magnesium

casting by about 1 kg over 3 development generations.